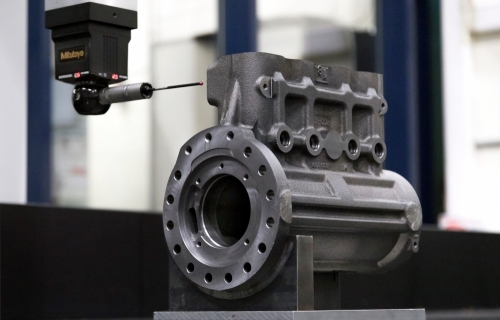

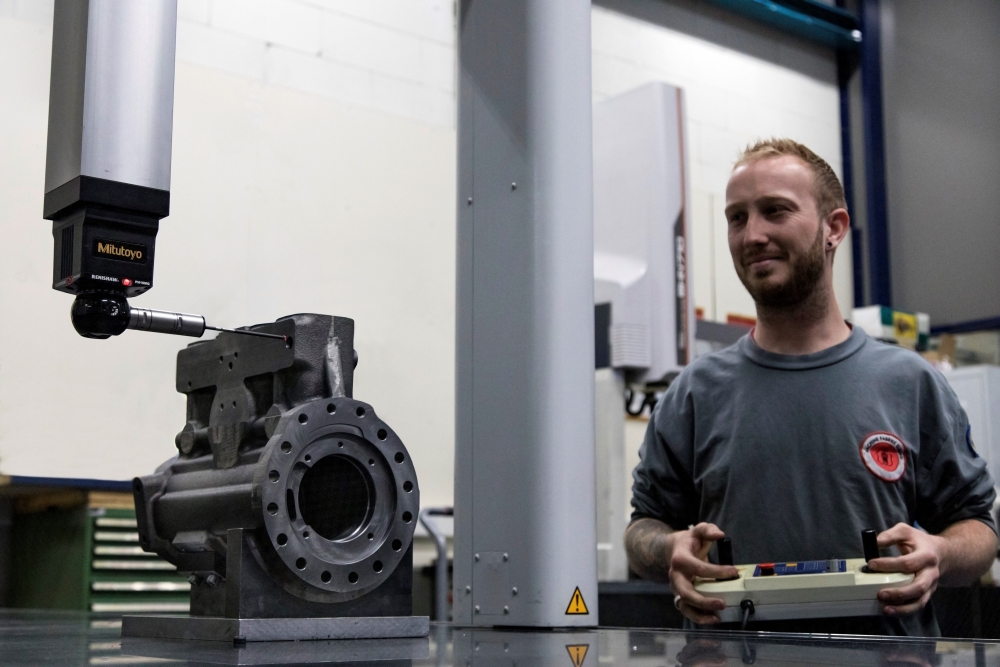

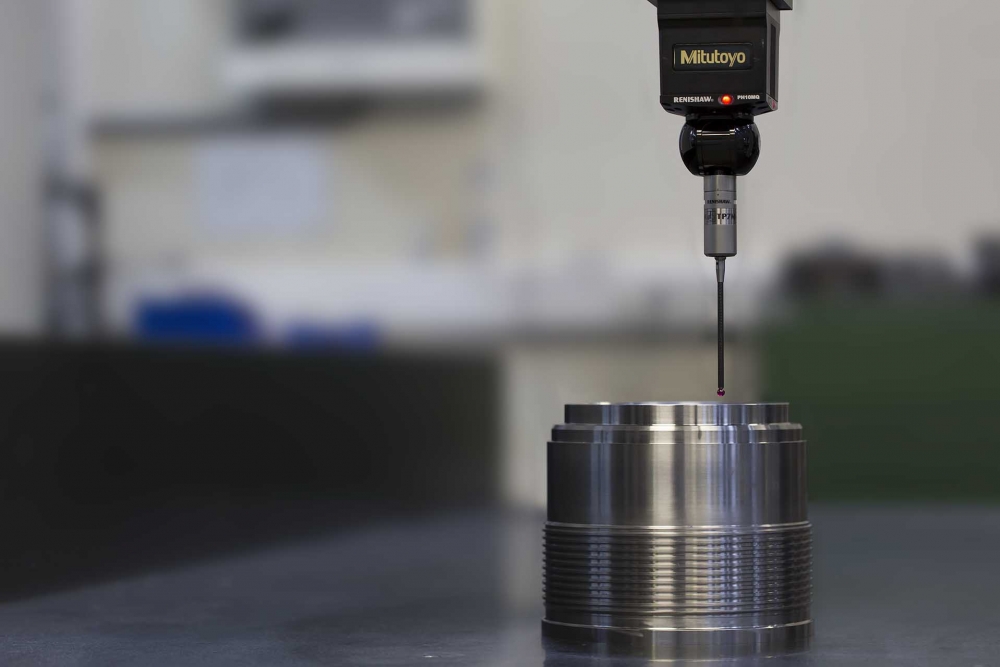

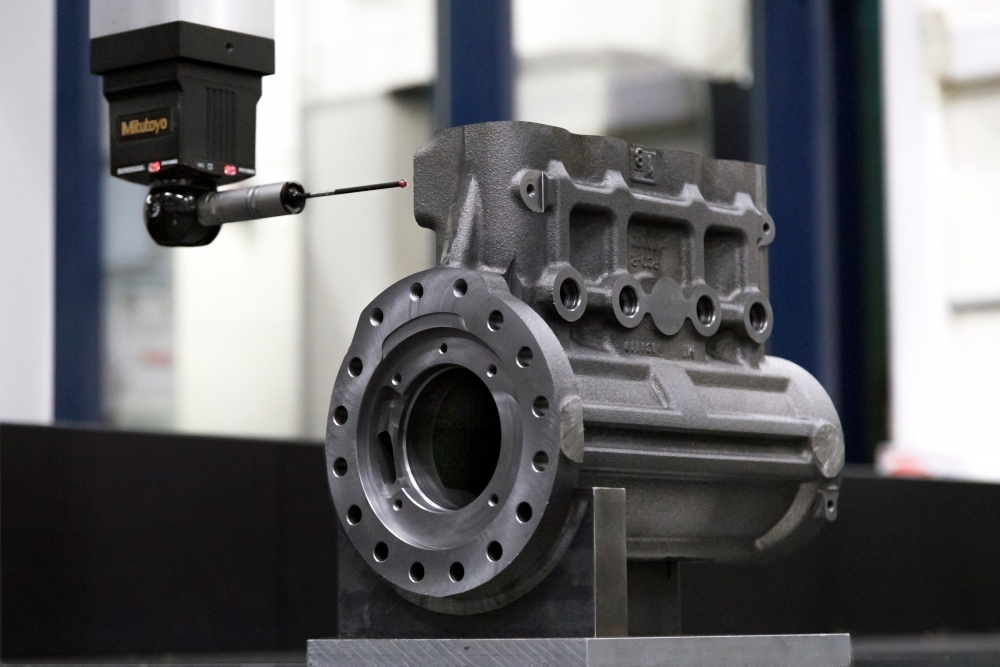

Met gestroomlijnde processen, hoogwaardig –machinepark , meetmiddelen en een geconditioneerde meetkamer met 3 Mitutoyo meetmachines, zijn wij in staat u kwalitatief hoogstaand werk te leveren. Periodiek wordt ons systeem getoetst tegen de norm ISO9001 en IATF16949. Deze laatste norm ligt zijn oorsprong van in de Automotive, echter worden deze technieken bij Machine Fabriek Elburg ook al meer toegepast in de Non Automotive. (APQP, PPAP, FMEA, SPC, MSA)

The Automotive Quality Core Tools are the building blocks of an effective quality management system. They include Advanced Product Quality Planning & Control Plan (APQP), Production Part Approval Process (PPAP), Failure Mode and Effects Analysis (FMEA), Statistical Process Control (SPC) and Measurement System Analysis (MSA)

Bekijk onze meetmachinesVeiligheid en Milieu staat bij Machine Fabriek Elburg ook standaard op de agenda in de afdelingsgesprekken. Wij zijn gecertificeerd tegen de ISO14001 en laten jaarlijks een Risico –inventarisatie uitvoeren door een externe partij, zodat wij inzichtelijk krijgen waar onze risico’s liggen. Periodieke toetsing vindt plaats.

Machine Fabriek Elburg is met een aantal werknemers bevoegd materialen om te stempelen en te keuren volgens norm EN10204-3.1/3.2 (Stempelbevoegdheid)