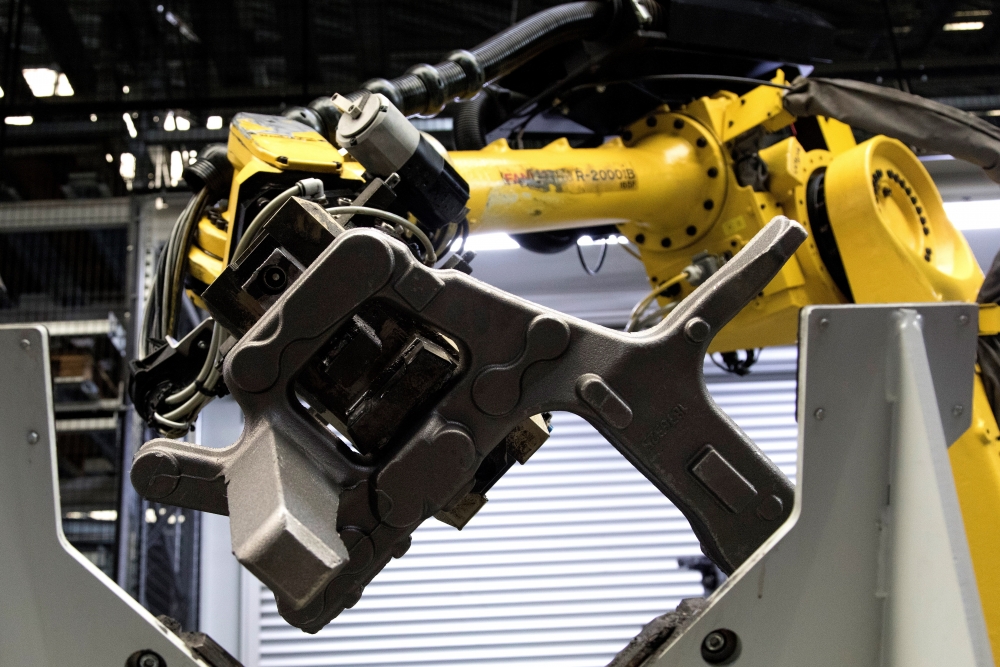

Machine Fabriek Elburg is equipped with a Flexible Manufacturing System (FMS) with a length of 65.5 metres and a height of 6.8 metres. In addition to the fully-automatic pallet changer, five horizontal processing centres, two robots and three manual loading systems are currently integrated into this system. In order to feed these integrated systems for production purposes, the system offers a storage capacity for 71 machine tables, 296 Europallets and 95 gitterboxes.

The FMS is set up in such a way that it can operate twenty-four hours a day and seven days a week.

With the integration of two robots and three manual loading systems, the FMS is highly suitable for the production of both small and large recurring series.

Take a look at the video for more information about our Flexible Manufacturing System.

Quality is the foundation of our company. This not only applies to Machine Fabriek Elburg’s production output, but also to our machine park, the use of assets/tools and of course our staff. Machine Fabriek Elburg strives to keep its quality at the highest possible level in all regards.

Continuous improvement is a key concern and an ongoing process at Machine Fabriek Elburg.

Machine Fabriek Elburg sets itself apart with its extensive work preparation process. At Machine Fabriek Elburg, the necessary tools, clamping moulds, machine programmes, measuring tools and the measuring programme are all carefully thought out and prepared before a production process starts in earnest. With this approach, we can reduce the set-up times of products and keep lead times as short as possible.